Application

RITTER Bellows-type Gas Meters are applicable for measuring the volume of flowing inert and dry gases and are particularly effective at high gas flows. Please note that gases containing aggressive components or water vapour may reduce the life span of bellows-type gas meters, if the casing of the measuring unit (tinplate), the valve/control elements (polyamide) or the bellows (Perbunan®) should be attacked. Further details on the materials that may come into contact with gases can be found under Materials.

The desired measurement range can be selected from among 6 magnitudes (types) extending together as a whole from 40 ltr/h to 160 m3/h at a gas temperature ranging from +5 °C to +40 °C. The solidly soldered casing on the standard model is designed to withstand a maximum overpressure of 50 mbar (BG 40/100: 0.5 bar).Advantages

The major advantage and the superiority of volumetric gas meters (like bellows-type gas meters) over other measurement principles, which determine gas volume using secondary measurable variables such as speed, heat capacity, hot-wire resistance or similar, is that the volume is directly measured by the principle of displacement. That means that the condition and the composition of the gas has no influence on the measurement accuracy.The measurement principle and the design of the measuring unit enables a measuring accuracy of ±2%.

Correcting factors which take into account gas type, temperature, humidity etc are therefore not necessary(1). It should be noted that with other, non-volumetric measurement processes, the measurement accuracy given for that process can only be achieved if the correcting factors for the immediate condition of the gas are exactly known. The RITTER Bellows-type Gas Meters need no maintenance and no set-up prior to the measurement. They are easy to carry, don’t need a power supply (unless equipped with option »Pulse Generator«) and can therefore used »in the field as well without problems. (1) The measurement of temperature and pressure is necessary, if the measured and indicated actual volume of gas must be recalculated into the norm volume (as with any measurement of gas volume).Performance Data

| Tipo | Portata Minimo (ltr/h) | Portata Massimo (ltr/h) | Portata Standard (ltr/h) (1) | Indicazione di lettura Minimo (ltr) (2) | Indicazione di lettura Massimo (ltr) (2) | Pressione massima di ingresso del gas (mbar) |

|---|---|---|---|---|---|---|

| BG 4 | 40 | 6000 | 3000 | 0,1 | 99999999 | 300 |

| BG 6 | 60 | 10000 | 5000 | 0,2 | 99999999 | 300 |

| BG 10 | 100 | 16000 | 10000 | 0,5 | 999999990 | 50 |

| BG 16 | 160 | 25000 | 15000 | 0,4 | 999999990 | 50 |

| BG 40 | 400 | 65000 | 39000 | 0,4 | 999999990 | 500 |

| BG 100 | 1000 | 160000 | 95000 | 0,4 | 999999990 | 500 |

(1) La calibrazione viene eseguita a portata standard e 20 °C (68 °F)

(2) Divisione quadrante minima

Precisione di misura: +/- 2% a portata standard e 20 ° C (il valore esatto è indicato nel singolo certificato di calibrazione)

Intervallo di temperatura: +5 °C a +40 °C

Non è possibile la direzione del flusso inverso!

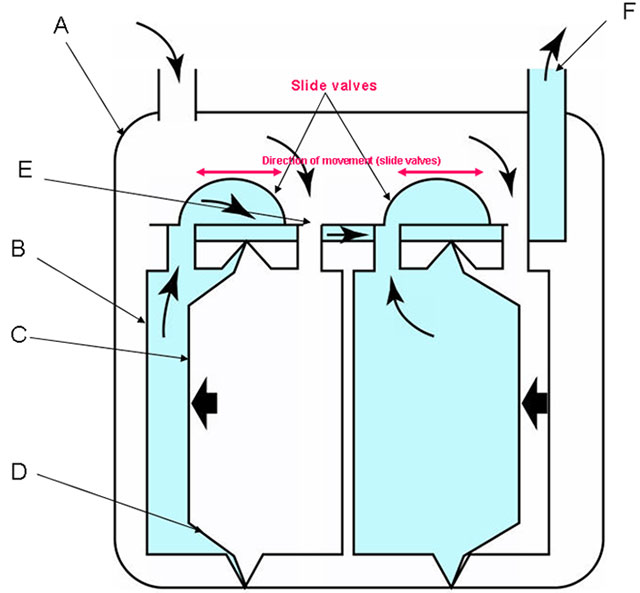

Measurement Principle

- Outer casing of the meter: Material: Zinc-coated steel sheet (soldered) with outside also lacquered.

- Casing of the identical twin chambers of the Meter. Material: Tinplate

- Non-flexible part of membrane. Material: Tinplate sheets. Flexible part of membrane.

- Material: Textile-reinforced nitrile rubber (Perbunan).

- Gas entry to the chamber.

- Gas outlet

Equipment

- Accoppiamento magnetico (tra il tamburo di misurazione e il meccanismo di conteggio), per un involucro a tenuta stagna

- Collegamento del tubo del gas: filettatura in pollici

- Contatore a rulli totalizzatore a 8 cifre

- Unità di misura a doppia camera

Materials

- Casing:

- Measuring unit: Tinplate

- Bellows (within measuring unit): Textile-reinforced Perbunan

- Rod linkage: BG 4: Polyamide; all others: Polyamide/brass

- Slide gate: Bakelite

Built-in Options

- Display LCD , resettable, 8-digit (replaces Totalizing Roller Counter)

- Generatore di impulsi , versione standard o a prova di esplosione (per il collegamento di unità di visualizzazione elettronica / computer

Accessories (external)

- Termometro (BG)

- Manometro per pressione pmax = 60 mbar

- Unità di visualizzazione elettronica »EDU 32 FP« , visualizza il volume e calcola la portata via RS232 e l'uscita analogica in tempo reale (è necessario un generatore di impulsi)

- Ugelli per il collegamento di tubi flessibili