User Benefits

- Highest accuracy: ±0,5% across full flow rate range

- Calibration traceable to the German National Primary Standard (PTB)

- Measurement of all gases and gas mixtures with equal accuracy

- Use with extremely corrosive and inert gases

- Lowest measurable flow rates

- Largest selection of measuring ranges

- Real time data acquisition option for PC (requires option »Pulse Generator«)

- Most durable construction – available, both chemically (from high-quality thermoplastics) and mechanically (stainless steel)

- Maintenance-free (just checking of packing liquid level required)

Performance Specifications

| Type | Flow Rate Minimum (ltr/h) | Flow Rate Maximum (ltr/h) | Flow Rate Standard (ltr/h) (1) | Readout Indication Minimum (ltr) (2) | Readout Indication Maximum (ltr) | Measuring Drum Volume (ltr) | Pressure Loss Minimum (mbar) |

|---|---|---|---|---|---|---|---|

| TG 0.5 | 1 | 60 | 50 | 0.002 | 9,999,999.9 | 0.5 | 0.4 |

| TG 1 | 2 | 120 | 100 | 0.01 | 99,999,999 | 1.0 | 0.2 |

| TG 3 | 6 | 360 | 300 | 0.02 | 99,999,999 | 3.0 | 0.2 |

| TG 5 | 10 | 600 | 500 | 0.02 | 99,999,999 | 5.0 | 0.2 |

| TG 10 | 20 | 1,200 | 1,000 | 0.1 | 99,999,999 | 10.0 | 0.1 |

| TG 20 | 40 | 4,000 | 3,200 | 0.2 | 999,999,990 | 20.0 | 0.1 |

| TG 25 | 50 | 7,000 | 5,000 | 0.1 | 999,999,990 | 25.0 | 0.1 |

| TG 50 | 100 | 18,000 | 10,000 | 0.5 | 999,999,990 | 50.0 | 0.1 |

(1) The calibration is performed at standard flow and 20 °C (68 °F)

(2) Minimum dial division

The maximum gas inlet overpressure is dependent on the gas meter type and casing material:

With plastic casings TG05 – TG5: Standard version 50 mbar

With plastic casings TG10 – TG50: 50 mbar

With stainless steel casings: 0.5 to 40 bar

Measuring accuracy: ± 0.2% at standard flow rate (exact value is stated in individual Calibration Certificate) and approx. ± 0.5% across the entire measuring range.

Available Models (Materials)

| Material Number | Casing Material | Measuring Drum Material |

|---|---|---|

| 01 | Stainless steel | PVC-grey |

| 02 | Stainless steel | PE-el |

| 03 | Stainless steel | PP-grey |

| 04 | Stainless steel | PVDF |

| 05 | PVC-transparent | PVC-grey |

| 06 | PP-grey | PP-grey |

| 07 | PVDF | PVDF |

| 08 | PE-el | PE-el |

| Legend | ||

|---|---|---|

| PE-el | = | Polyethylene-electrically conductive |

| PP | = | Polypropylene |

| PVC | = | Polyvinyl chloride |

| PVDF | = | Polyvinylidene fluoride |

| Stainless steel | = | 1.4571 |

| Viton | = | Fluorine rubber |

For chemical resistance properties please contact your RITTER distribution partner.

Application

RITTER Drum-type (wet-test) Gas Meters are universally applicable for measuring the volume of flowing gases and are particularly effective when measurements demand the highest precision. The possibility of selecting the gas meter material from among 5 different excellent materials: Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylide Fluoride (PVDF), PE-el (polyethylene electrically conductive) or refined stainless steel 1.4571 (316 Ti) enables the user individually to meet measurement requirements even in case of highly aggressive gases. For rugged, industrial applications, robust models with a stainless steel casing and plastic drum (four different materials) are available. The desired measurement range can be selected from among 8 sizes (types) extending as a whole from 1 Ltr/h to 18,000 Ltr/h at a gas temperature ranging from -10 °C to +80 °C. The solidly manufactured casing of the standard meters is designed to withstand a maximum overpressure of 50 mbar (plastic casings) or 500 mbar (stainless steel casings); meters for higher pressure ranges up to 40 bars are available. The measurement of RITTER Drum-type Gas Meters works on the principle of displacement. The gas meters contain a revolving measuring mechanism (measuring drum) within a packing liquid (usual: water or low-viscosity oil). The measuring drum compulsorily measures volume by periodically filling and emptying four rigid measuring chambers. Fastidious production methods and calibration enable a measuring accuracy of ± 0.2% at standard flow rate and approx. ± 0.5% across the entire measuring range. The major advantage and the superiority of volumetric gas meters (like drum-type gas meters) over other measurement principles, which determine gas volume using secondary measurable variables such as speed, heat capacity, hot-wire resistance or similar, is the direct measurement of volume. That means that the condition and the composition of the gas have no influence on the measurement accuracy. Correcting factors which take into account gas type, temperature, humidity etc are therefore not necessary. It should be noted that with other, non-volumetric measurements the accuracy given for that measurement can only be achieved if the correcting factors for the actual gas condition or gas mixture are exactly known.Advantages

Advantages of Drum-type Meters in General

The direct measurement of volume is the major advantage and the superiority of volumetric gas meters (like drum-type gas meters) over other measurement principles, which determine gas volume using secondary measurable variables such as speed, heat capacity, hot-wire resistance or similar. That means that the condition and the composition of the gas do not influence the measurement accuracy.Correcting factors which take into account gas type, temperature, humidity etc are therefore not necessary. It should be noted that with other, non-volumetric measurements the accuracy given for that measurement can only be achieved if the correcting factors for the actual gas condition or gas mixture are exactly known.

The drum-type meters need no maintenance and no power supply (unless equipped with option »Pulse Generator).Advantages of RITTER Drum-type Meters

- Casing and Measuring Drum out of superior plastics

RITTER Drum-type Gas Meters are specifically designed for use with corrosive gases. They are made out of a selection of 4 superior plastics (PVC, PP, PVDF and electrically-conductive PE). A gas meter can therefore be selected which is completely resistant to the corrosive gases being measured. Stainless steel is not completely resistant to corrosive gases and will be damaged by them over time.

Even RITTER’s Gas Meters with a stainless steel casing have a measuring drum made out of one of these high quality thermoplastics. This is because the measuring drum is the most important part of the gas meter and also the most susceptible to the effects of corrosive gases. - Measuring Drum is welded – not soft soldered

Competitor meters have a stainless steel casing and a measuring drum that is also made out of stainless steel. Because the steel plates used to make these measuring drums have to be so thin, they can only be soft soldered together. Soft solder weldings are eaten away by aggressive gases very easily! So even when the stainless steel itself is fairly resistant to corrosive gases, the soft soldering is not. This can cause the measuring drum to completely fall apart when the soft soldering is eaten away.

The measuring drum parts in RITTER Gas Meters are welded together with exactly the same material that the drum is made out of. PVC drums are welded together with PVC rods; PP drums with PP rods, PVDF drums with PVDF rods and PE drums with PE rods. The welds in RITTER Gas Meters are therefore as corrosion-resistant as the material used to build the drums. - Casing and Measuring Drum resistant against Packing Liquid – if turned into an acid

All drum-type gas meters contain a Packing Liquid – usually water. If the measuring drum is stainless steel and is used to measure a gas which reacts with water to form an acidic solution, the acidic solution can eat through the part of the measuring drum sitting under the water-line. This occurs most rapidly in gas meters which are not used very often. RITTER Gas Meters do not have this problem. - No epoxy coating needed for measuring drums

Some gas meter manufacturers offer stainless steel measuring drums with epoxy coating. It is very difficult to apply the coating completely evenly on the drum surface, especially in the sharp corners of the drum (where the soft solder welds are). These are weak spots where corrosive gases can even more easily start to attack and destroy the drum material and soft solder welds. - Magnetic Coupling instead of O-ring for drum axis

Competitor stainless steel gas meters have an axis which must go through the casing wall to connect the measuring drum to the needle indicator on the gas meter dial face. These meters have an O-ring or similar to seal the hole in the casing where the axis goes through. This O-Ring is under the packing liquid level. Because of the mechanical friction of the axis turning in the O-Ring, the O-Ring eventually begins to wear out.

If a gas has reacted with the packing liquid and turned it acidic, this acidic solution also begins to eat into the O-Ring material. Sooner or later the O-ring starts leaking. This causes the level of the packing liquid to drop. This drop in packing liquid level causes the gas meter to measure inaccurately. At first, when leakage is small, the drop in packing liquid level may not be realised by the user, so he/she does not realise that the measurement is wrong. If this leak becomes greater, the acidic packing liquid which leaks into the counter mechanism casing can damage the parts there.

RITTER uses a magnetic coupling system to connect the measuring drum to the needle indicator on the gas meter dial face. This means that there is no hole in the casing wall, and no O-Ring. The casing wall remains solid, and so there is no possibility of packing liquid leaking out. The gas meter remains gas and liquid-tight for its lifetime. - Transparent casing with PVC Gas Meters

If dirty gases are measured, the rotation of a drum-type gas meter measuring drum acts like a washing machine and forces the »dirt« out of the gas. This sediment builds up on the bottom of the gas meter casing. If it builds up too much it can hit the measuring drum, either slowing it down or making it stop altogether. If it slows it down, the measuring accuracy is affected without the user knowing. If it stops the rotation of the drum, it ruins that test run completely. With stainless steel gas meters, the user cannot check how much sediment has built up on the bottom of the gas meter casing and so does not know if the test runs are being affected.

RITTER PVC Gas Meters have a transparent casing, which means that this sediment build-up can be very easily monitored. The gas meter can be taken off-line before the sediment build-up can affect measurement accuracy or ruin test runs. It can then be cleaned between runs. - RITTER Meters can be repaired

If a stainless steel gas meter has been epoxy-coated, it is very difficult, if not impossible, to repair. This is because epoxy-coated parts cannot be re-welded. Because of this, some stainless steel gas meter manufacturers refuse to repair these meters. When they do repair, these repairs can be very expensive. This is because undamaged epoxy-coated parts have to sometimes be removed to get to the damaged parts in the meter. Because the undamaged epoxy-coated parts cannot be re-welded, they have to be replaced along with the damaged parts.

The thermoplastics which RITTER uses to build gas meters can be re-welded. That means that only the truly damaged parts need to be replaced. This makes RITTER repairs economical.

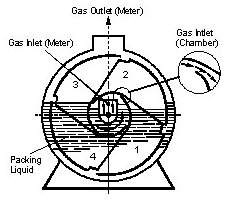

Measurement Principle

Phase 1

Chamber 1: Beginning of filling (into space above packing liquid)

Chamber 2: During filling

Chamber 3: Emptying

Chamber 4: Not active

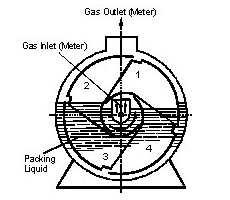

Phase 2

Chamber 1: During filling

Chamber 2: Emptying

Chamber 3: Not active

Chamber 4: Beginning of filling (into space above packing liquid)

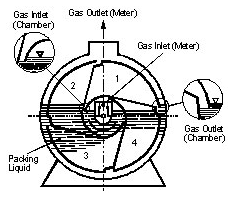

Phase 3

Chamber 1: Filling completed / Chamber inlet & outlet closed

Chamber 2: Emptying

Chamber 3: Not active

Chamber 4: Filling

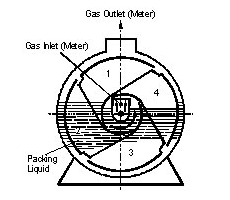

Phase 4

Chamber 1: Emptying

Chamber 2: Emptying

Chamber 3: Filling

Chamber 4: Just beginning to fill

Equipment

- 8-digit Totalizing Roller Counter

- Bubble level for levelling

- Level and Levelling Feet

- Magnetic coupling between measuring drum and counter: Casing absolutely liquid-tight, for an absolutely liquid-tight casing

- Multi-Chamber Measuring Drum

- Supports for Thermometer and Manometer

- Viton sealing

Accessories

Built-in Options

- LCD Display , resettable, 8-digit (replaces Totalizing Roller Counter)

- Pulse Generator , standard or Ex-proof version (for connecting Electronic Display Unit/Computer)

- High Precision Packing Liquid Level Indicator »HPLI« , for packing liquid level

Accessories (external)

- Data Acquisition Software »RIGAMO« , (for Windows)

- Thermometer Gas (TG) , measuring range 0 °C to +60 °C

- Thermometer Packing Liquid (TG) , measuring range 0 °C to +60 °C

- Manometer for pressure pmax ≤ 50 mbar , measuring range 0-10 / 0-20 / 0-50 mbar

- Manometer for pressure pmax ≤ 1 bar , measuring range 0-600 mbar / 0-1 bar

- Manometer for pressure pmax ≤ 10 bar , measuring range 0-6 / 0-10 bar; available for higher pressure ranges

- Electronic Display Unit »EDU 32 FP« , displays volume and calculates flow rate via RS232 and analog-output in realtime (pulse generator required)

Packing liquids

- HCl solution 1.8 vol% for gas mixtures with CO2

- Packing Liquid Pionier 4281 , only for drum-type gas meters (TG)

- Packing Liquid Silox for gas mixtures without CO2

- Packing Liquid CalRiX , only for drum-type gas meters (TG)

Data-sheets

TG Plastic (≤500mbar)

TG Stainless steel (≤1bar)

TG Stainless steel (>1bar)

- TG 0.5 Stainless steel 6 bar

- TG 1 Stainless steel 6 bar

- TG 1 Stainless steel 10 bar

- TG 1 Stainless steel 16 bar

- TG 1 Stainless steel 35 bar

- TG 3 Stainless steel 6 bar

- TG 3 Stainless steel 10 bar

- TG 5 Stainless steel 6 bar

- TG 10 Stainless steel 6 bar

- TG 20 Stainless steel 6 bar

- TG 25 Stainless steel 6 bar

- TG 25 Stainless steel 10 bar

- TG 50 Stainless steel 6 bar