Overview

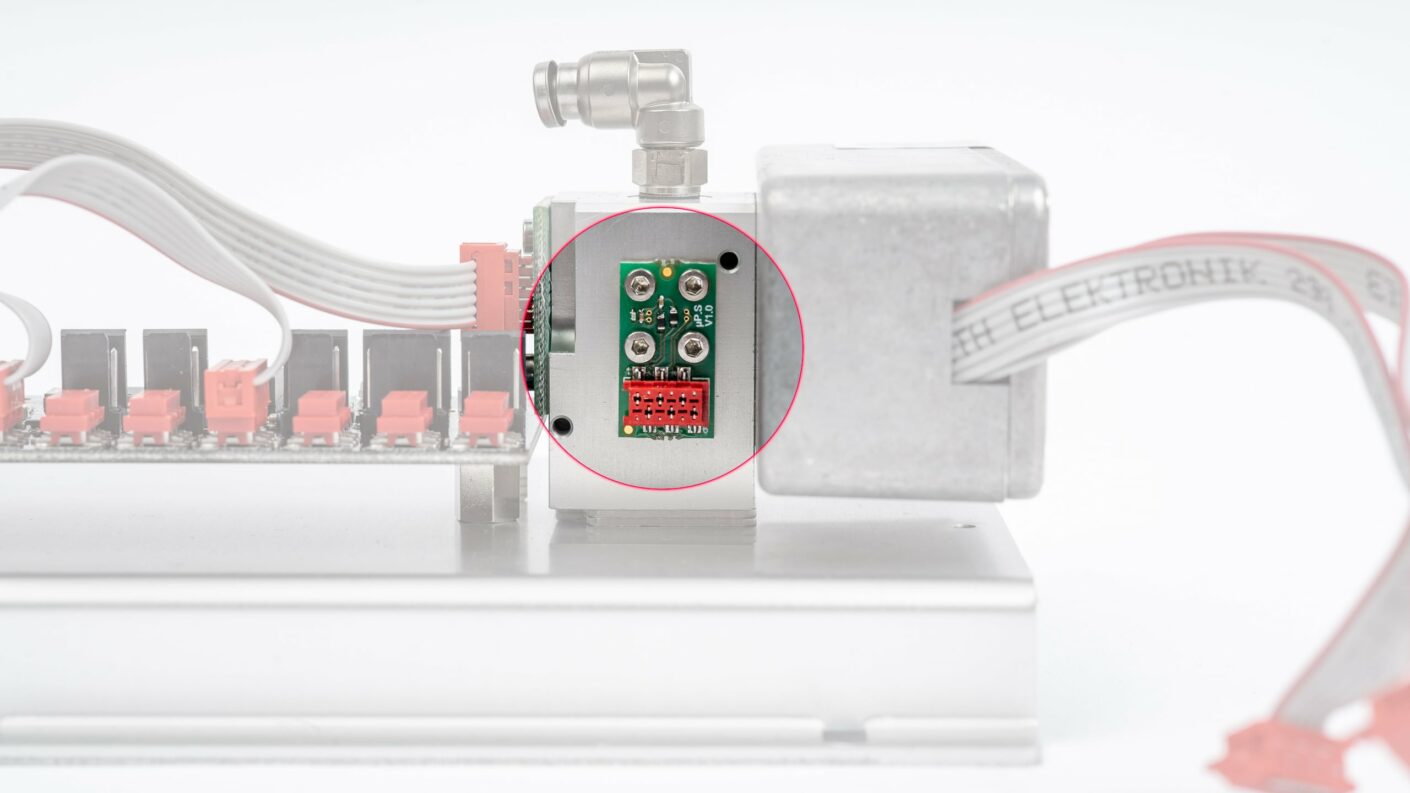

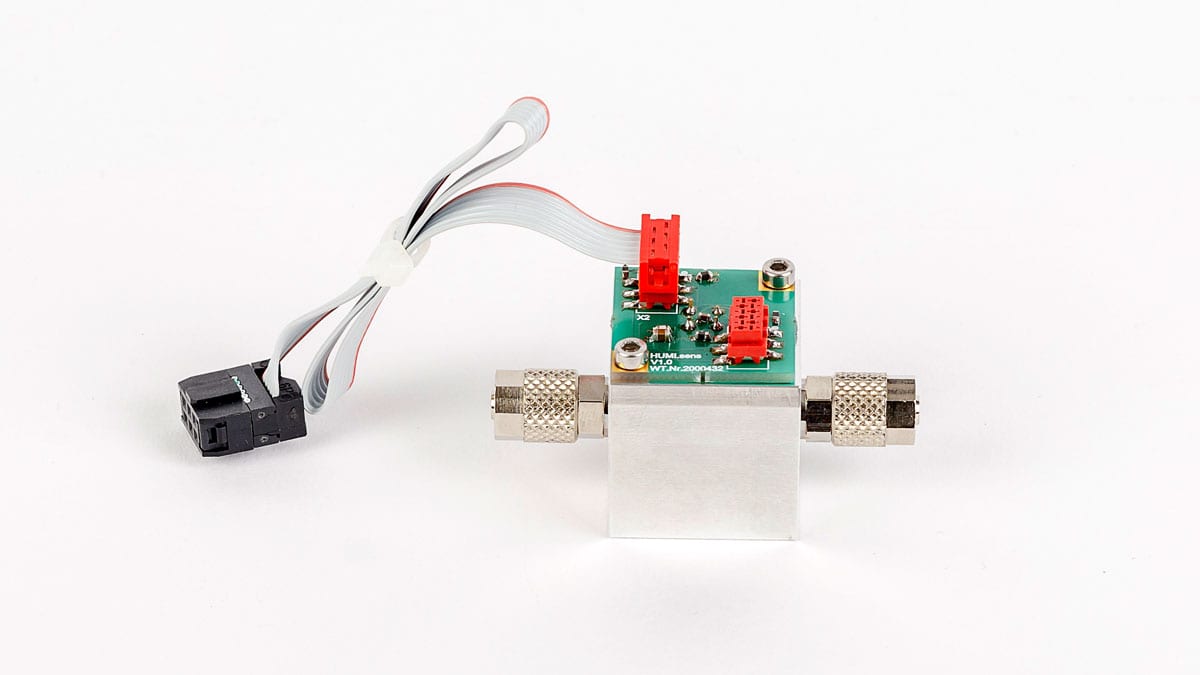

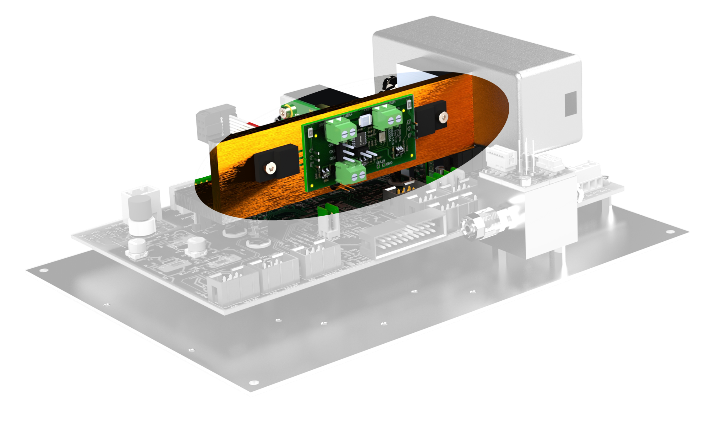

The RITTER MultiGas Sensors NDUV Module (non-dispersive UV sensor) has also been specially developed for use in high quality gas analysis. In the design phase special emphasis was placed on high stability and a low detection limit. These goals could be fully achieved by using high-performance light-emitting diodes (UV-LED) and gas discharge lamps (EDL) which were adapted to the requirements of gas detection technology. In the spectral range from 200 nm to 405 nm, nitrogen oxides, aromatic hydrocarbons, ketones, ozone, sulfur dioxide and halogens can be used with this novel sensor platform, partly detected reliably in the ppb range.

Applications

- Biogas research

- Environmental measuring technology

- Elemental analysis

- Industrial gas analysis

- Process measuring technology

Characteristics and Benefits

- Group of detectable gases: O3 CL2 H2S SO2 NO2

- Measurement technology: Innovative NDUV-Sensor (non-dispersive ultraviolet sensor)

- Measurement accuracy ±2% of Full Scale (F.S.)

- No cross-sensitivity to H2

- Operating temperature: 5 – 45 °C

- Operating pressure: 800 – 1200 mbar (hPa) abs.

- Flow rate range: 1 ltr/day – 100 ltr/h

- Warm-up time: 1 min

- Response time (t90): ≈ 1-2 sec depending on gas

- In tabletop casing, overall dimensions W x H x L 171 x 85 x 246 mm, weight approx. 1,9 kg

- Gas connection: PVDF screw-type tube connection for tube Øi 4 mm, Øa 6 mm

- Power supply: 24 VDC (incl. power plug 100 – 240 VAC / 24 VDC)

In contrast to photometric NDUV sensors the lifetime of electrochemical sensors for measurement of H2S is limited. Please note that lifetime data for such sensors are given for air and not for measurement of H2S. For H2S concentrations > 200 ppm the lifetime is reduced, for concentrations > 1000 ppm critical. While the measurement performance of UV-LED is constant, EC sensors are becoming »deaf«.

Recalibration

- Readjustment of the zero-point is recommended once a week.

- Contamination of the measuring cuvette can lead to shifting of the end-point. Due to the integrated filter, re-adjustment of the end-point is generally not required – but can be performed once a year.

- Additionally, cartridges filled with an inert and the respective test gas for recalibration of the zero and end-point can be provided.

- Long-term drift is < 1% of Full Scale (F.S.) / 24 h.

V 1.0 / Rev. 2023-03-21 / Subject to alterations.

The most recent version of this data-sheet can be found at …

https://dlr.ritter.de/en/products/multigas-sensors/multigas-ultraviolet-module-nduv/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

For questions please contact mailbox@ritter.de or your local distribution partner (on our overview page)

https://dlr.ritter.de/en/products/multigas-sensors/multigas-ultraviolet-module-nduv/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

For questions please contact mailbox@ritter.de or your local distribution partner (on our overview page)