Overview

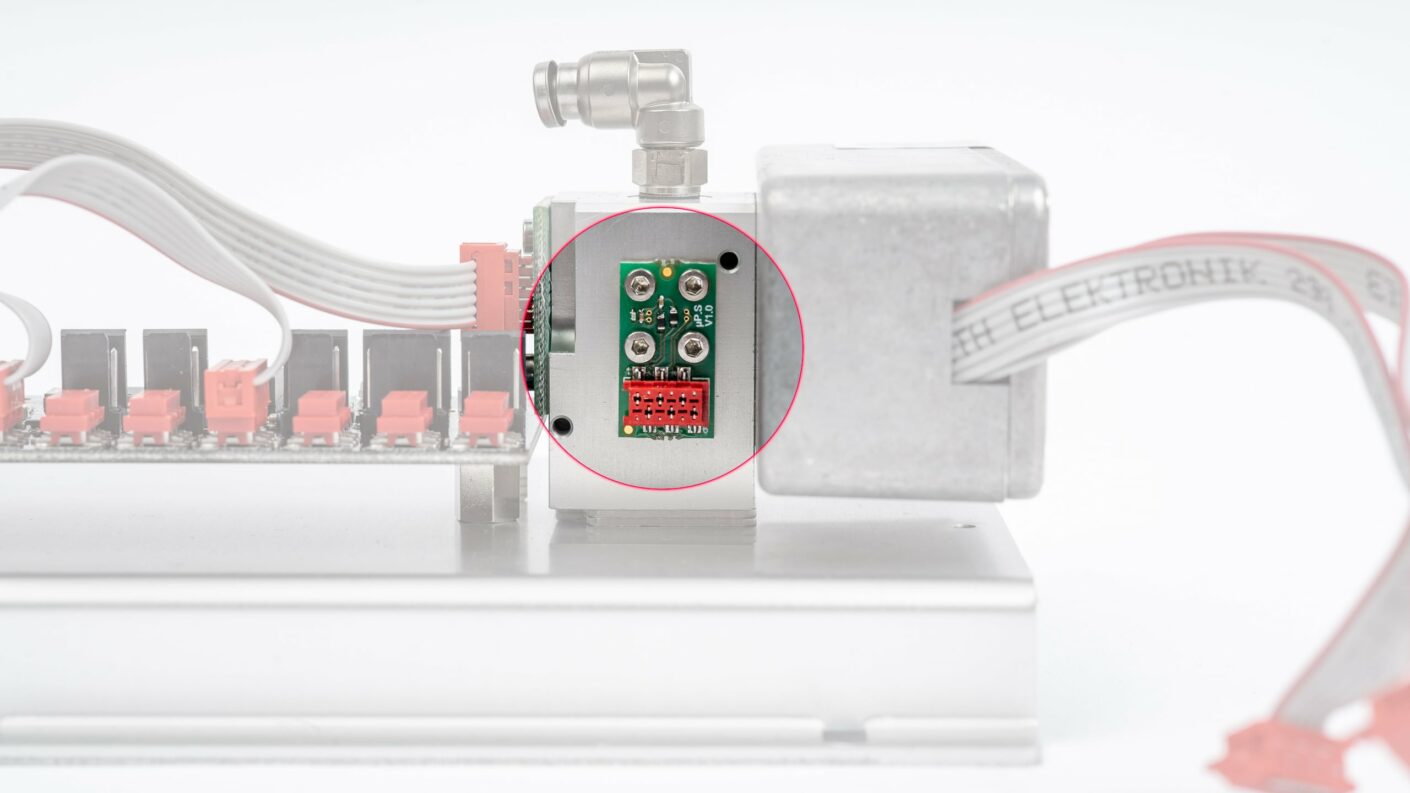

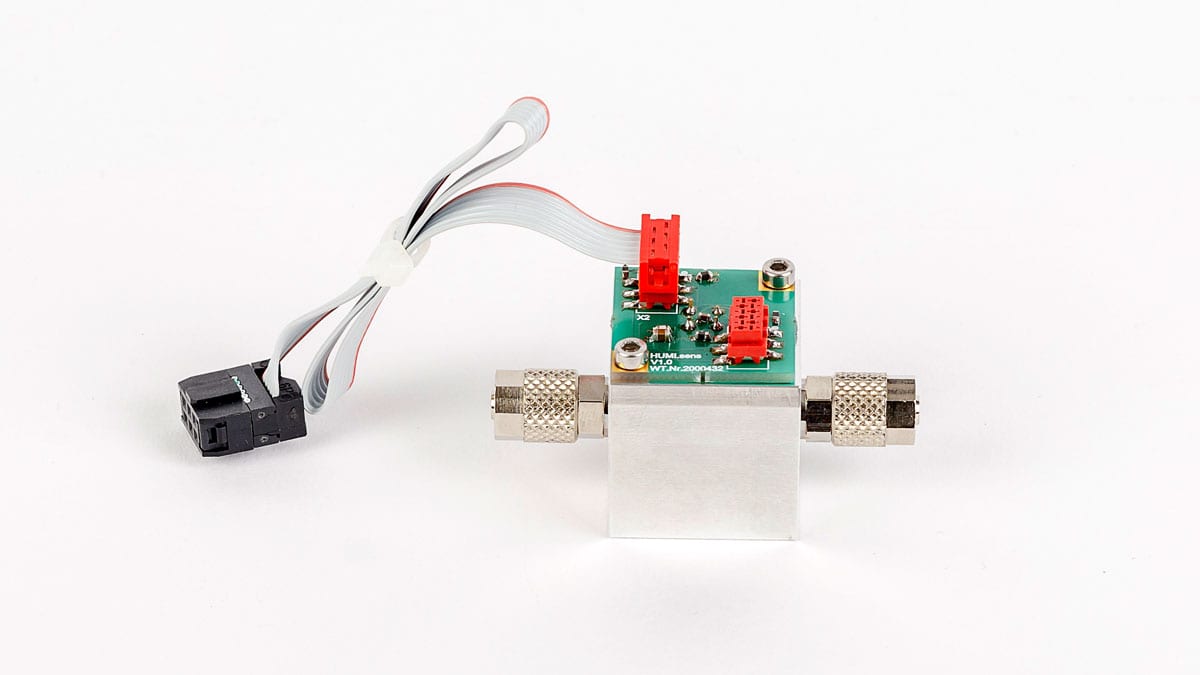

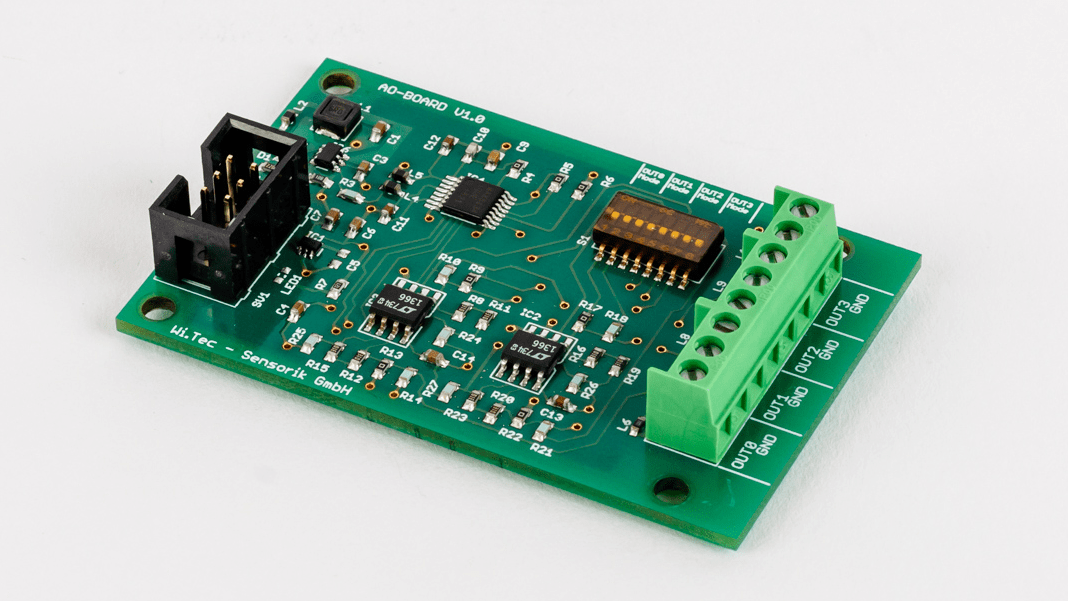

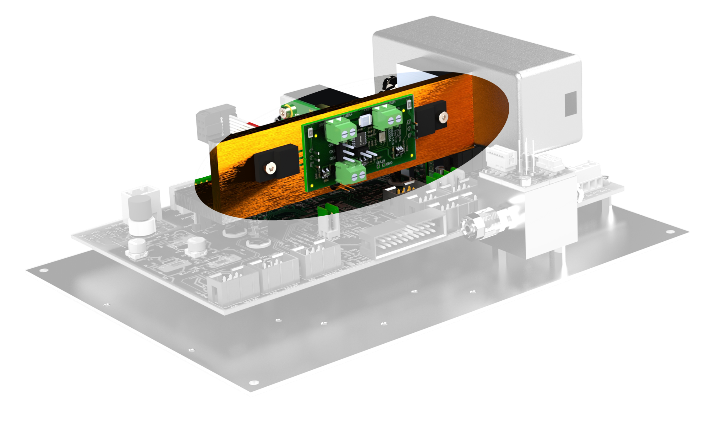

The RITTER MultiGas Sensors NDIR Module (non-dispersive IR sensor) has been specially developed for use in high-quality gas analysis. In the design phase special emphasis was placed on high stability and a low detection limit. These goals could be fully achieved by using high-performance light-emitting diodes (IR-LED) and thermal micro-radiators which were adapted to the requirements of gas detection. In the spectral range from 2 μm to 12 μm, carbon dioxide, carbon monoxide, hydrocarbons, water vapor and sulfur hexafluoride can be safely detected down to the ppm range with this innovative sensor platform.

Applications

- Biogas research

- Environmental and process measuring technology

- Elemental analysis

- TOC-analyzers

- Industrial gas analysis

- Natural gas analysis

Characteristics and Benefits

- Group of detectable gases: CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

- Measurement technology: NDIR-Sensor (non-dispersive IR sensor)

- Measurement accuracy ±2% of Full Scale (F.S.)

- No cross-sensitivity to H2

- Operating temperature: 5 – 45 °C

- Operating pressure: 800 – 1200 mbar (hPa) abs.

- Flow rate range: 1 ltr/day – 100 ltr/h

- Warm-up time: 2 min

- Response time (t90): ≈ 3 sec

- Interface USB, on request RS 232

- Sensor cuvette: Aluminum, gold plated for sensor length 100 ≥ mm

- Incl. temperature compensation

- Incl. data acquisition software

- In tabletop casing, overall dimensions W x H x L 171 x 85 x 246 mm, weight approx. 1,9 kg

- Gas connection: PVDF screw-type tube connection for tube Øi 4 mm, Øa 6 mm

- Power supply: 24 VDC (incl. power plug 100 – 240 VAC / 24 VDC)

Recalibration

- Readjustment of the zero-point is recommended once a week.

- Contamination of the measuring cuvette can lead to shifting of the end-point. Due to the integrated filter, re-adjustment of the end-point is generally not required – but can be performed once a year.

- Additionally, cartridges filled with an inert and the respective test gas for recalibration of the zero and end-point can be provided.

- Long-term drift is < 1% of Full Scale (F.S.) / 24 h.

Downloads

V 1.0 / Rev. 2023-03-21 / Subject to alterations.

The most recent version of this data-sheet can be found at …

https://dlr.ritter.de/en/products/multigas-sensors/multigas-infrared-module-ndir/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

For questions please contact mailbox@ritter.de or your local distribution partner (on our overview page)

https://dlr.ritter.de/en/products/multigas-sensors/multigas-infrared-module-ndir/

Dr.-Ing. RITTER Apparatebau GmbH & Co. KG · Coloniastrasse 19-23 · D-44892 Bochum · Germany

For questions please contact mailbox@ritter.de or your local distribution partner (on our overview page)